The construction of a typical DP transmitter can be seen in the below diagram:

A differential pressure capsule is mounted inside a housing. A connection is given between one end of a force bar and the capsule assembly so that the motion of the capsule can be transmitted outside the housing. A sealing mechanism is used where the force bar penetrates the housing and also acts as the pivot point for the force bar. The housing is constructed in such a way that the high pressure fluid can be applied on one side of the capsule and low pressure fluid on the other side. Thus causing the creation of the difference in pressure which will cause the capsule to deflect and create motion in the force bar. The top end of the force bar is then connected to a position detector, which via an electronic system will produce a 4 - 20 mA signal that is proportional to the force bar movement.

The DP transmitter installation diagram can be seen below:

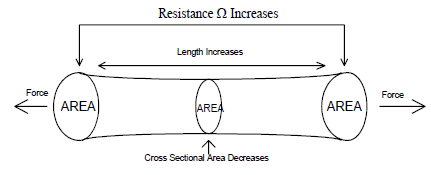

Apart from this type of measurement method, the other method that can be used is Strain Gauges:

Strain gauge is a device that can be affixed to the surface of an object to detect the force applied to the object. One form of strain gauge is a metal wire of very small diameter that is attached to the surface of a device being monitored.

No comments:

Post a Comment